THE STEEL PROCESSING CENTER

Highly specialized engineers and designers accompany the customer from the early stages of architectural design to the executive design and construction of the work, using of the most innovative BIM software for the design of the structures and the management of production in the workshop.

Innovation and development through investments in advanced technology guarantee high qualitative and quantitative performances. We satisfy the needs of the most demanding customers, guaranteeing quality, safety, reliability and efficiency. The execution of the steel structures is certified UNI EN ISO 1090-2 execution class EXC4 (CE mark)

We propose ourselves as the only interlocutor for the customer in the construction of the steel structure. We complete the production process - within the same site - with hot galvanizing, and finally we take care of transport to the construction site and assembly, for a turnkey solution that optimizes time and costs.

The modern steel processing center is equipped with many CNC machines and offers assembly and welding service.

WHAT WE CAN DO

2 CNC machines for sheet metal cutting and drilling

- Plasma and oxy-fuel cutting

- Max dim. workable: 15.000 x 3.000 x 150 mm

- Chip removal drilling

- Threading, milling, crimping, scribing

CNC machine for cutting and drilling of profiles

- Max dim. workable: 12.500 x 600 x 1.000 mm

- Straight or angled cut

- Chip removal drilling

- Scribing

Bending press

- Max. Workable 6.200 mm

- Bending force 250 ton

Shear

- Hydraulic guillottine shear

- Max. Workable 6.050 x 4 mm

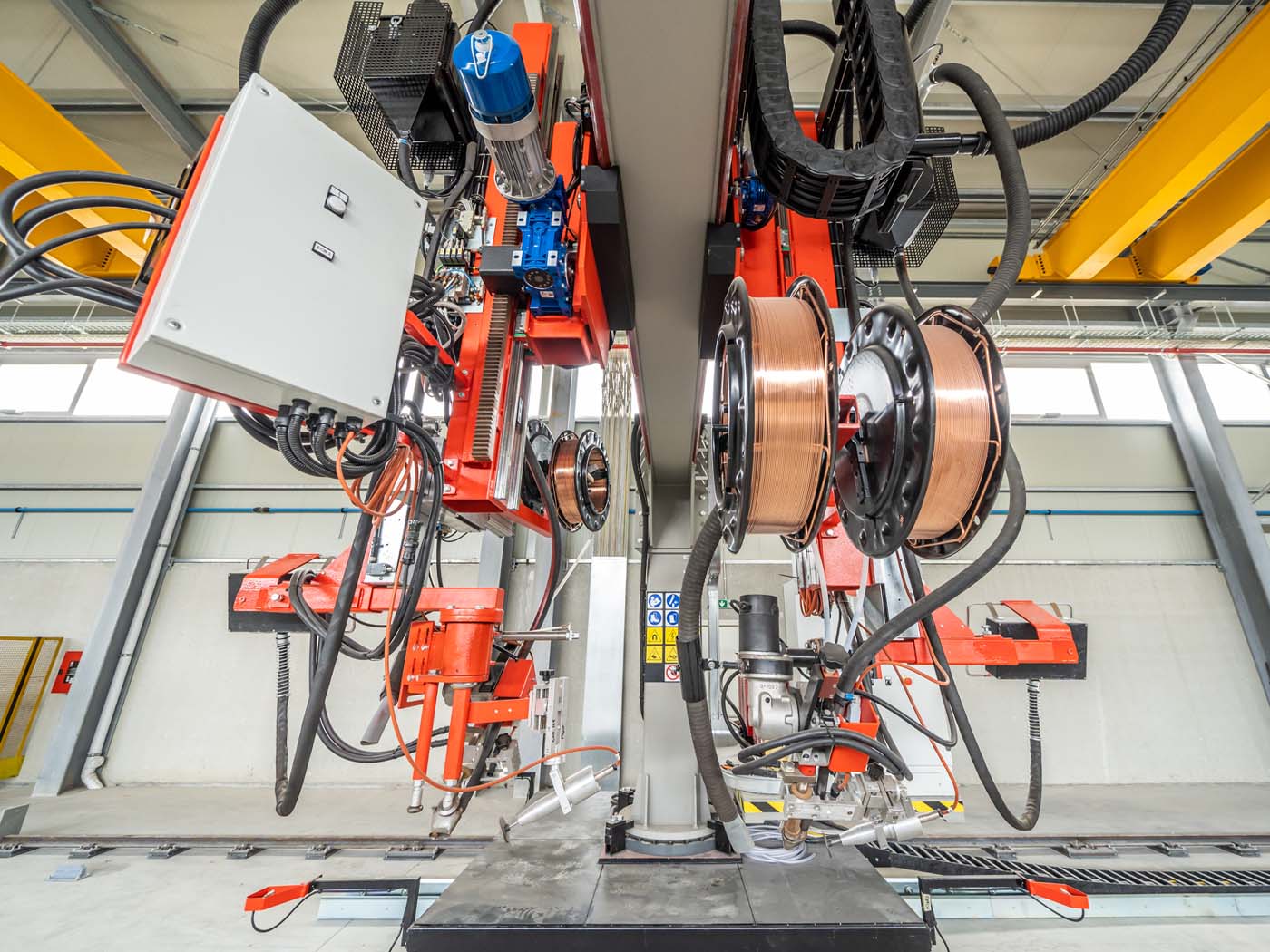

Submersible arc welding

- 2 automatic welders moving in parallel on a 30m long rail

- H or caisson beams

- Max height 2.500 mm

- Max width: 1.000 mm

- Thickness from 5 mm to 50 mm

Manual assembly and welding

A large area is intended for assembly and continuous wire welding: the welding process is UNI EN ISO 3834 certified performed by UNI EN ISO 9606 certified welders with latest generation welding machines.

We create hot-dip galvanized steel structures for hospitals, bridges, highways, industrial warehouses, commercial buildings, roofs, safety stairs, piers, photovoltaic canopies and any other project that the customer proposes to us.

SEE

OUR PROJECTS

OUR SERVICES

ARCHITECTURAL DESIGN

STRUCTURAL CALCULATION

EXECUTIVE MACHINERY DESIGN

PRODUCTION

TRANSPORT

ASSEMBLY